New Projects Boost U.S. LNG Export Capacity: EIA

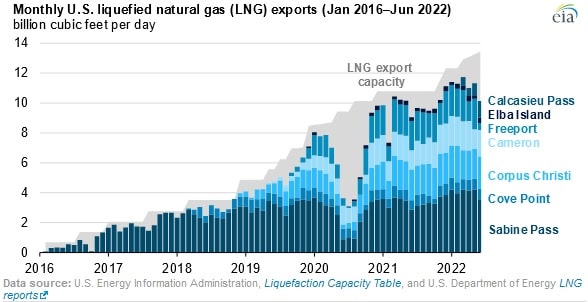

The U.S. has the largest liquefied natural gas export capacity in the world and emerged as the top exporter as of July 2022, according to a Sep. 6 report from the U.S. Energy Information Administration. U.S. LNG exports averaged 11.2 billion cubic feet per day (bcf/d) during the first half of 2022, up by 12 percent compared to the same period in 2021.

The increase can be attributed to several reasons including enhanced LNG export capacity, higher global natural gas, and LNG prices, and firm world demand, most notably in Europe. Moreover, record profitability margins for U.S. LNG producers in Asia, Europe, and the UK have further incentivized exports. LNG exports from the Lower 48 states began in February 2016. Previously, the U.S. had only exported LNG from Alaska and occasionally reexported LNG from the Lower 48 import terminals.

U.S. export capacity has increased by a 2.1 bcf/d peak since November 2021. The capacity increment incorporates a sixth train at the Sabine Pass LNG, 18 new mid-scale liquefaction trains at the Calcasieu Pass LNG, and enhanced LNG production capacity at Sabine Pass and Corpus Christi LNG facilities.

Calcasieu Pass LNG, the seventh and most recent LNG export project, commissioned all its liquefaction trains ahead of schedule in August 2022. Also, another two gulf coast projects have recently begun construction along with Golden Pass LNG, which started in 2019.

Golden Pass LNG consists of three standard-size trains with peak capacities of 0.8 bcf/d, totaling 2.4 bcf/d. Since the project will take place on the site of an existing regasification facility, the construction is expected to be faster and more cost-effective.

Plaquemines LNG has 24 mid-scale trains rated at 0.07 bcf/d peak capacity. The liquefaction trains are each part of a two-unit block, for a total of 12 blocks generating 1.8 bcf/d.

Corpus Christi Stage III facility is located at the site where there are currently three liquefaction trains operating. It has 14 new mid-scale trains under construction with a peak capacity of 0.11 bcf/d. The trains are made up of two-unit blocks for a total of seven blocks with a combined peak capacity of 1.6 bcf/d.

Corpus Christi Stage III and Plaquemines LNG use mid-scale refrigeration trains, which have a shorter timeline for construction. Calcasieu Pass LNG, which is also based on the same technology, became operational 2.5 years after its final investment decision which is the shortest construction period to date for any US LNG export project.

EnerKnol Pulses like this one are powered by the EnerKnol Platform—the first comprehensive database for real-time energy policy tracking. Sign up for a free trial below for access to key regulatory data and deep industry insights across the energy spectrum.

ACCESS FREE TRIAL